Stencils are usually made from metal or other materials with holes, which are used for soldering paste applying on printed circuit boards in the SMD assembly process.

Laser cut stencils – are made from steel with high power laser. They provide the highest assembly quality. Thanks to the laser, walls of holes are pitched (cone section, wider from board side). Due to that, while removing a stencil from a board,the paste stays on the board and the layer of paste is placed on pads in equal thickness plating. The execution cost of a laser stencil depends on 2 factors: stencil’s surface (quantity of material) and working time of laser, therefore it highly dependents on the quantity of holes.

Chemically etched stencils – made from steel or proper alloy. Steel sheet is covered (by photochemical method) from both sides by protective substance, leaving only uncovered blank, in which holes will be placed. Then stencils are immersed in pickling bath on specified time until acids chemically etched stencil through. Assembly with chemically etched stencil is of lower quality than a laser stencil. Execution cost of this stencil does not depend on the number of holes ,in the case of highly complicated board, cost can be several times lower than in the case of a laser stencil.

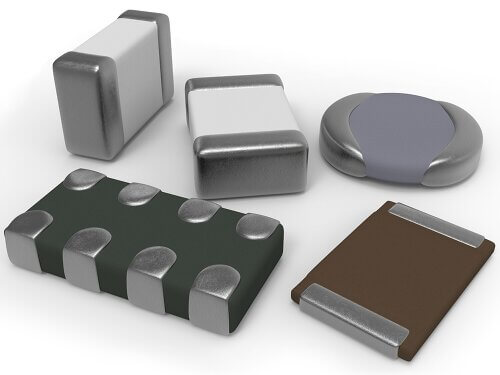

Metal stencils – both, laser and chemically etched are made from steel sheet – thickness – 0.1mm, 0.12mm, 0.15mm, 0.18mm (standard – 0.12mm).

Drilled stencils – made from epoxy laminate, holes are made with a drilled method (by numerical drill). Before manufacturing the stencil, gerber filles should be converted into drill fiels. In order to perform drilled stencils, 0.2-0.25mm thick laminates are used.

Evaluate your project

Fill out the form, we will contact you.