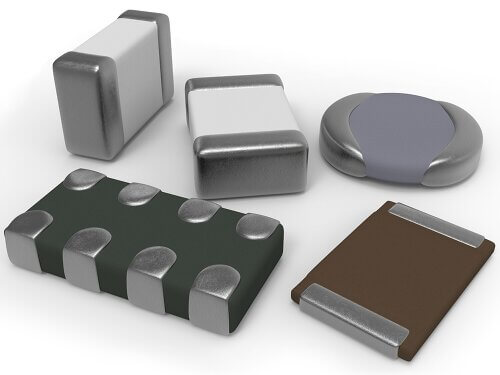

Depending on Customers’ requirements there are several possible ways to provide components for production. Generally we assemble entrusted components confided by a Customer (many Clients keep them in our warehouse), however a lot of Customers prefer the other option when we provide all of the materials necessary to production.

While choosing this option a Customer has the following advantages:

- does not have to worry about shopping,

- does not need to maintain storage of components,

- problem of post-production endings disappears,

- thanks to our contacts with local and foreign suppliers, we can offer very competitive prices, often not availble for retail Customers.

Ordering components abroad

While ordering components abroad, especially in the countries outside of the European Union, you may encounter many obsticles. Not only do you have to be registered in the international service, but also there is a lot of bureaucracy that you have to deal with. You need to have EORI number which is required by customs agencies and Customs. When the package gets to the European customs region, it has to be registered and the duty needs to be paid etc. Our company deals with these issues every day, therefore you do not have to worry about any additional paperwork. That is why, we encourage our Clients to order the components for them from such foreign suppliers as DIGI-KEY, MOUSER, OCTPART and others.

Hard to find components

Extremely important part of our offer are obsolete components (e.g. those which came out of production – obsolete components). Thanks to wide contacts with suppliers from the East and the USA, we can easily gain almost every component at a competitive price.

Obsolete components

We have access to the following obsolete components of integrated circuits: Altera, Xilinx and Silicon Laboratories. The products are brand new (date of production – 2011+), original and ready to use (on warranty).Products from our offer are even 50% cheaper from other distributors.The table below presents the comparison of prices.

SOLITECH is a supplier of paste stencils made with laser,chemically etched and drilled methods.

- Laser stencils recommended when on board are components with spacing 0.5mm or lower – regardless of the numbers of solder points .

- Chemically etched stencils recommended for projects with a great number of soldering points and when minimum SMD pad width is higher than 0.5mm

- Drilled stencils recommended only for elements with minimum space 0.8mm occur(the larger pads, the better). For example, they are good for soldering LED boards etc.

Mechanical tooling

Milling plotter MFG4025P allows us to offer a wide range of services related to mechanical tooling:

Customizing of aluminum and plastic housings

- maximal panel size 240x340mm

- minimum diameter of milled hole fi=1.0mm

Manufacture of aluminum front panels

- maximal panel size 240x340mm

- minimum diameter of milled hole fi=1.0mm

Carving printed circuit prototypes

- 1- or 2-layer, made by a carving method – the removal of copper foil out of laminate with a milling cutter and keepeing it in areas where traces, pads and vias are placed,

- holes (THT pads and vias) are unplated – to make conductive vias and pads, it is necessary to solder a thin wire through the hole,

- lack of soldermask and description.

- this technology is posisible only if the following parameters are met: minimum diameter of milled hole 24mil=0.6mm, minimum trace width / space 10mil=0.25mm

- price around 70PLN (17,50 EUR)/dm2 plus production preparation 50,00 PLN (12,50 EUR)

- execution time – 2 working days,

This service is recommended when prototype circuits are needed in limited quantities (max 5dm2) and in a very short time. If you want to order a greater amount or quick delivery is not important – we recommend to use our standard manufacturing service.

Additionally, we offer manufacture of electromagnetic shields – according to the given technical drawing. Shields are made of bent steel sheet and coated with solder layer which enables easy soldering.

Evaluate your project

Fill out the form, we will contact you.