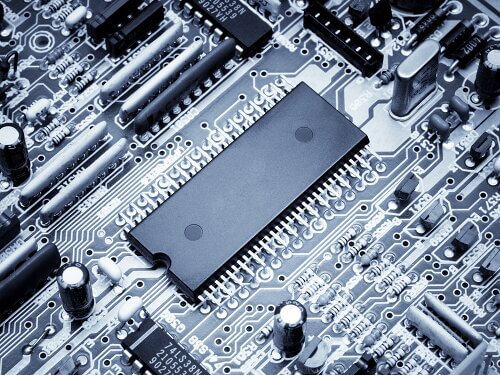

While designing printed circuit boards certain rules have to be followed. A board which is designed according to these rules will be not only technologically feasible but also assembly of components will be much easier.

The requirements are explained in the IPC-A-600D norm. We have enlisted some basic requirements which will help us to avoid mistakes in the future.

In gernaral, while designing a PCB the datasheet should be followed. However, sometimes it is good to do some exception to the rules:

- in the case of narrow raster of a pin -0.5mm,

- you should keep spacing between pads and pad’s width ought to be 0.25mm even if the producer provides different measurements. It would ensure optimal amout of solder paste for SMD assembly;

- integrated circuits pads in MLF/QFN housing should be lenghtened so that at least 0.5mm is extented beyond the contour of an integrated circuit;

- large pads (e.g. thermal pads with MLF/QFN housing)should be diveded into smaller parts on the paste layer. Thanks to that, we avoid the excess of paste on the pad.;

- when it comes to MLF/QFN housing it is worth doing a 2mm hole. Especially when a board’s prototype is to be maunted manually. As a result, it would be possible to get to the thermal pad with a soldering iron;

- It is advisable to divide the BGA packaging into 4 quarters in an organised way – equal in every quarter. In this way areas free from tracks occur and they can be used for condensers which regulate power supply.

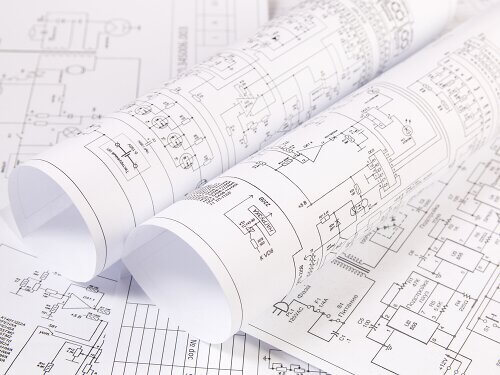

- If the pins are densely placed and are to get close together (be connected), we recommend to make the connection not directly. In the picture the pins on the left side of integrated circuit are made correctly, and those on the right are incorrect.

Evaluate your project

Fill out the form, we will contact you.