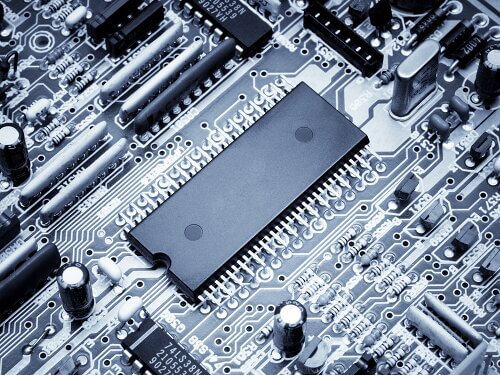

PCB (Printed Circuit Board) is made from dielectric material covered with traces and soldering/contact points of conductive material (copper Cu).

The most common dielectric materials:

- FR-4 – glass – epoxy laminate. It has good dielectric features (dielectric constant is 4,8 independently of temperature or moisture). At the same time it is mechanically resistant and absorbs poorly water. That is why, it is the most popular dielectric.

- CEM-1 – composite epoxy material (CEM), laminate with one layer of glass fabric, based on paper material.

- teflon – has an excellent dielectric material – also for very high frequency, therefore,it is often used in electronics,it does not absorb water, is more flexible than epoxy laminate.

Dielectric layer is from the one side (one-layer side) or two sides (two-side board) covered by copper foil. Usually copper layer thickness equals around 18um, 35um, 70um, 105um (assumed unit 1 OZ = 35um). All holes to metallization are made with numeric drilling machine(THT pads- used to through hole assembly and vias – holes by which traces could change course form one layer to another), next by electrochemical method (galvanization) metallization in this hole is conducted.

Next, in a photochemical way connections drawing are applied on them(traces, pads, vias) in substance protecting against chemicaly etched form. Then board is dipped in chemically etched bath (only unprotected surface are chemically etched). After that this substance is deleted, and both printed circuit board sides are covered (sieve-printing method)a by solder-mask – usually in green, with insulation properties, which protect vias, traces and uncover only soldering points. Soldering points are covered with different protective layers. The most popular are:

- ENIG – Electroless Nickel Immersion Gold

- HASL – unleaded HAL – tinning by tin alloy without lead

Additionally, by sieve- printing method, inscription is applied e.g. board name, assembly information etc.

Manufacturing technology of 4- and more -layer boards differs from the one described above. Such boards are executed by

Evaluate your project

Fill out the form, we will contact you.